Covers

Advanced Equipment

Annual Output

Xiangan now has a standardized modern workshop. It can reasonably argue processing equipment according work flow. Meanwhile, precision machining can be guaranteed after the introduction of standardized, modularized, and automatic equipment, like, the FIDIA 5-axis high-speed milling system, Quick Jet high-speed milling machine, KAFO CNC milling machine, double-head EDM, deep hole drilling machine,medium-and-large-scale closing machine, CNC wire-electrode cutting machine and trial molding equipment.

VIEW more

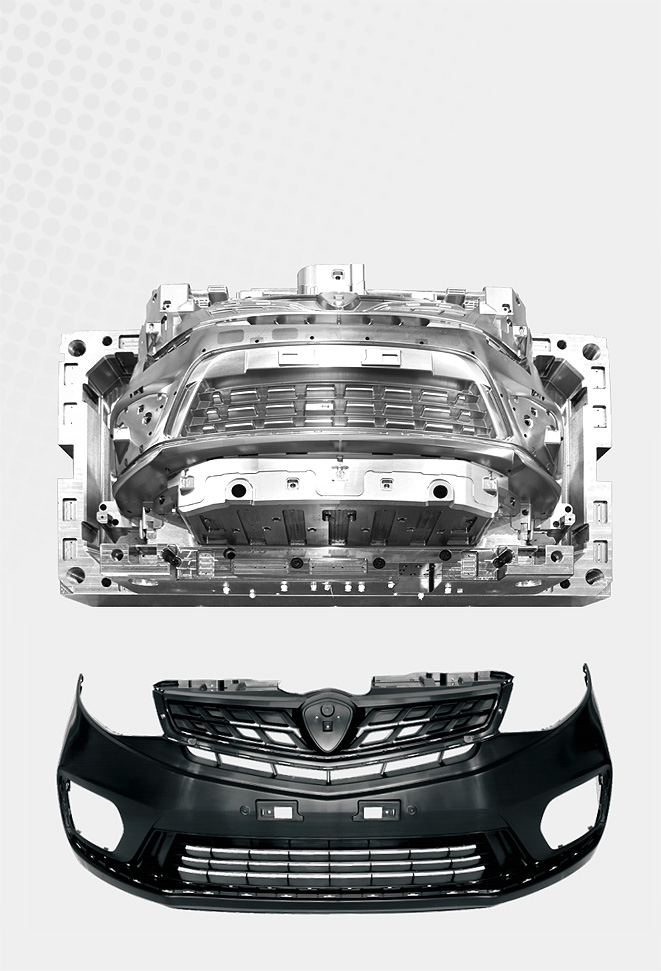

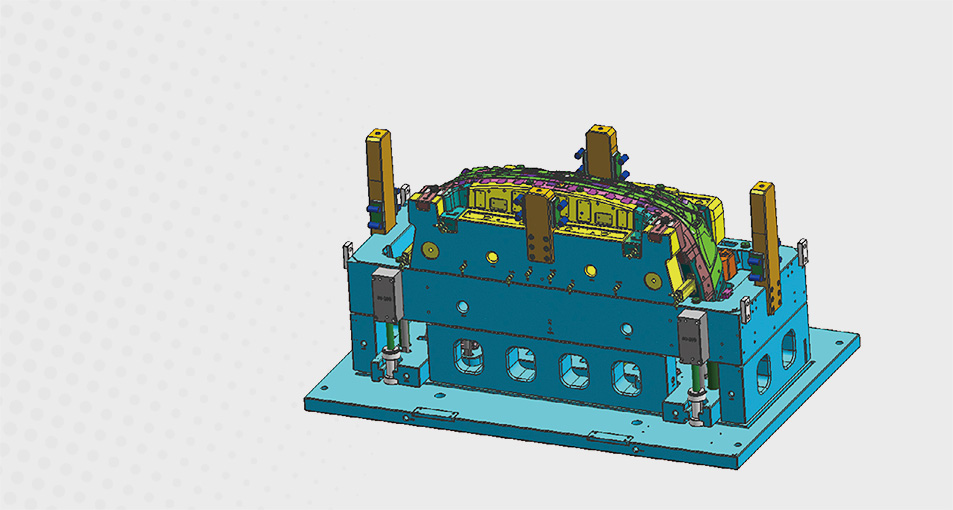

The company mainly produces automobile bumper, mask, dashboard, door guard, interior and exterior accessories and other large plastic molds.

The Specialized Automobile Plastic Moulds Supplier.

Lean Management, Careful Manufacturing, Customer Satisfaction, the Pursuit of Quality.

View Morecontact us