This technology is set to redefine the production of automobile instrument panels, promising enhanced durability, design flexibility, and significant production efficiencies.

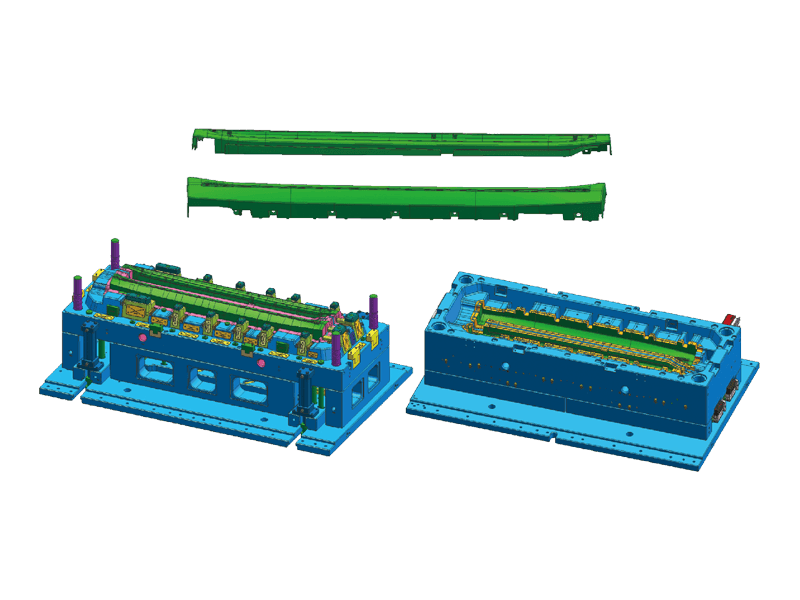

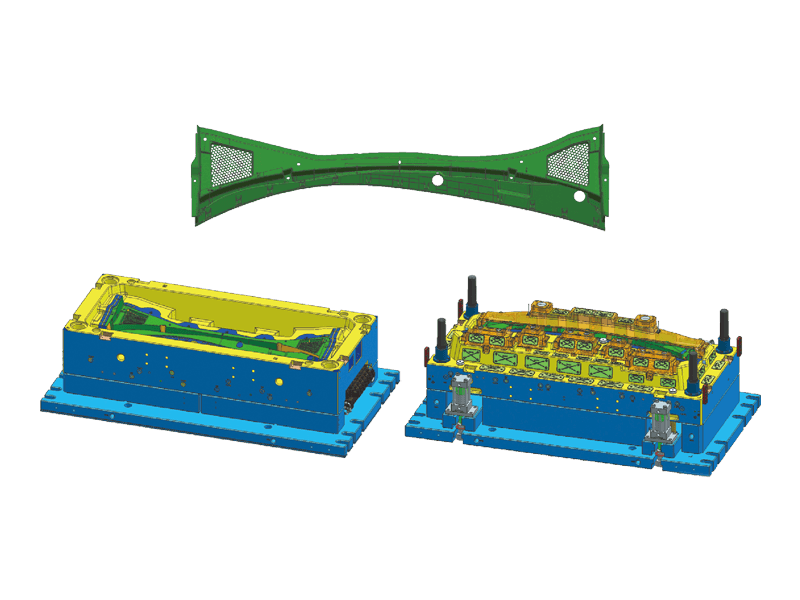

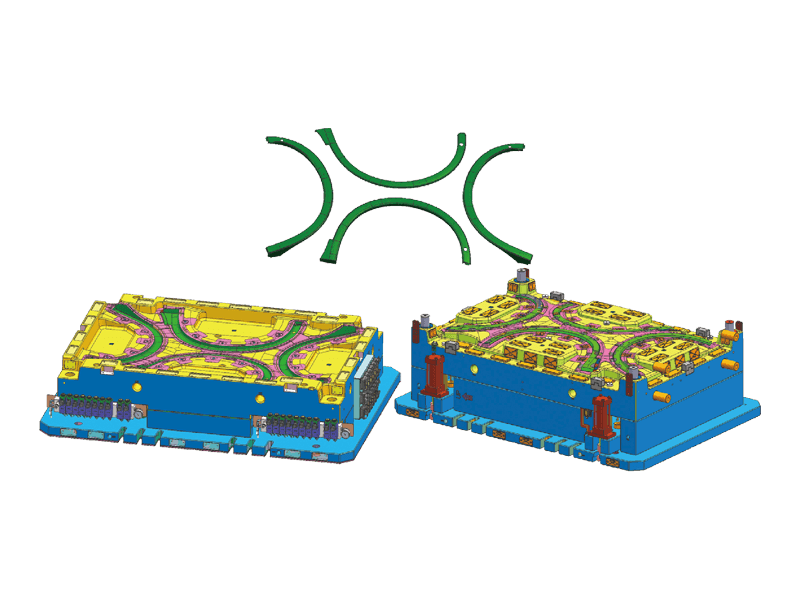

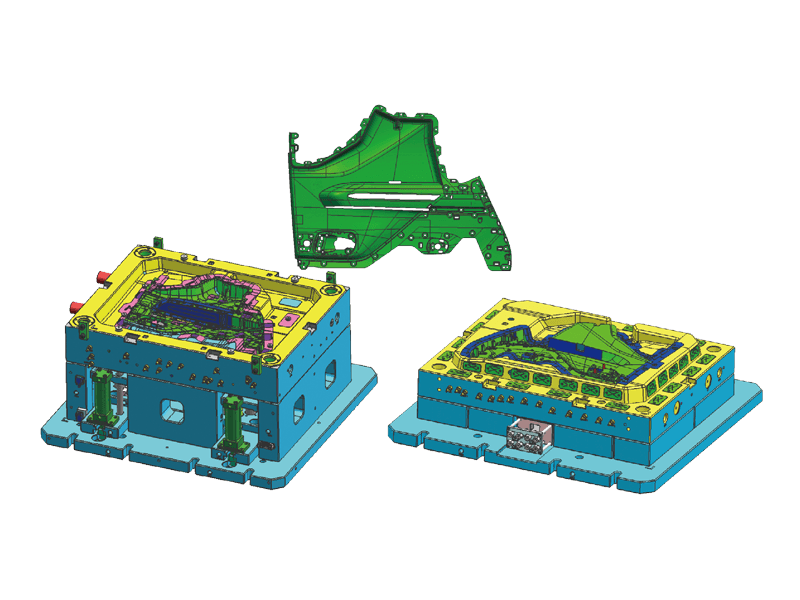

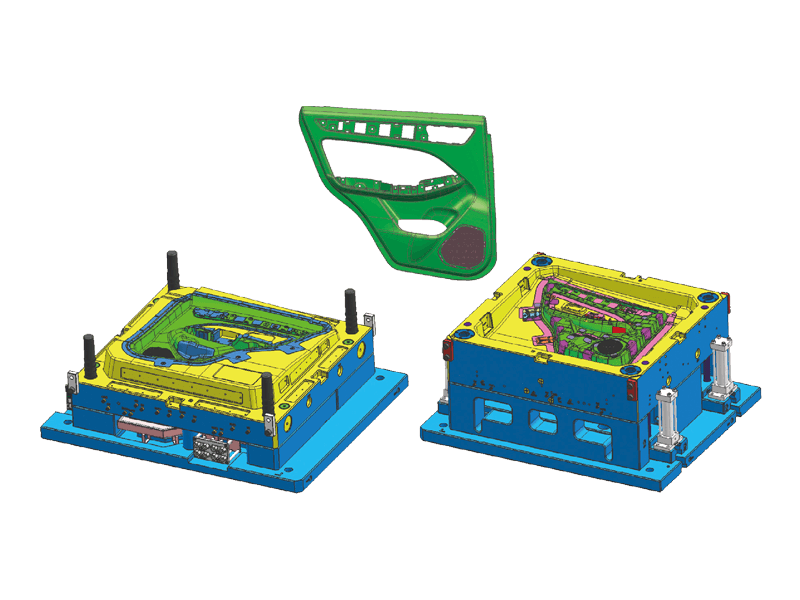

The introduction of the Automobile Instrument Panel Injection Mold marks a pivotal moment for the automotive industry. This innovative mold technology represents the forefront of design and engineering, offering a comprehensive solution for the creation of high-quality, aesthetically pleasing, and functional instrument panels. The Automobile Instrument Panel Injection Mold stands out for its ability to meet the increasing demands of modern automotive interiors, combining cutting-edge features with advanced manufacturing techniques.

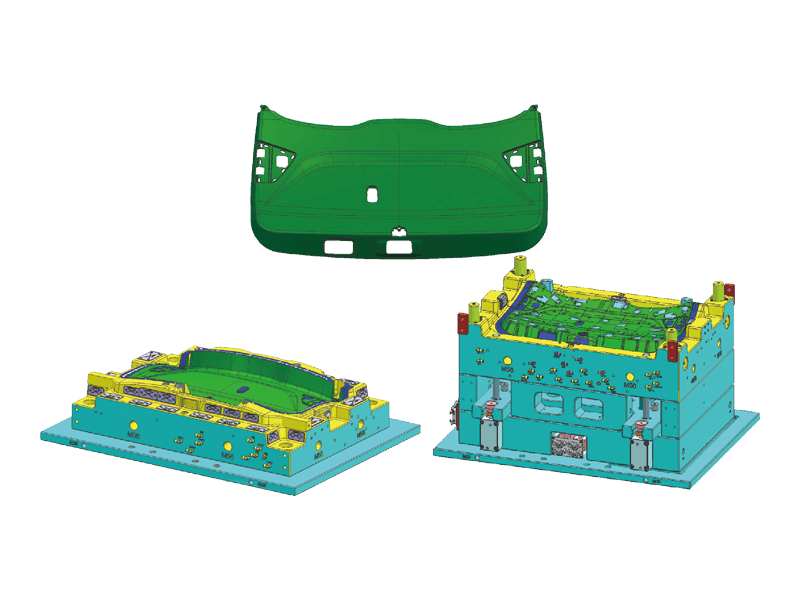

One of the primary advantages of the Automobile Instrument Panel Injection Mold is its exceptional durability and reliability. Constructed from high-strength, durable materials, this new mold technology is designed to produce instrument panels that withstand the rigors of everyday use. The Automobile Instrument Panel Injection Mold incorporates advanced structural features to ensure that each panel maintains its integrity and functionality over time. Rigorous testing and quality control processes are integral to the development of the Automobile Instrument Panel Injection Mold, guaranteeing that the final products meet the industry standards for durability and performance.

The Automobile Instrument Panel Injection Mold offers design capabilities that allow manufacturers to create instrument panels with greater complexity and detail. This advanced mold technology supports a wide range of design options, including intricate textures, customizable patterns, and innovative finishes. The Automobile Instrument Panel Injection Mold enables designers to push the boundaries of automotive interior aesthetics, resulting in instrument panels that are not only visually appealing but also align with the latest trends in automotive design. The flexibility provided by the Automobile Instrument Panel Injection Mold opens up new possibilities for creative and functional instrument panel designs.

Efficiency is a key feature of the Automobile Instrument Panel Injection Mold, making it a game-changer in the automotive manufacturing process. This advanced mold technology supports rapid production cycles, allowing manufacturers to produce high-quality instrument panels quickly and cost-effectively. The Automobile Instrument Panel Injection Mold is designed for streamlined production processes, reducing times and minimizing costs while maintaining high standards of quality. By optimizing production efficiency, the Automobile Instrument Panel Injection Mold provides significant benefits for manufacturers and consumers alike, contributing to a more efficient and cost-effective automotive manufacturing process.

AutoTech Solutions is dedicated to promoting sustainability, and the Automobile Instrument Panel Injection Mold reflects this commitment through environmentally friendly manufacturing practices. The production process for this mold technology incorporates the use of recyclable materials and energy-efficient methods. The Automobile Instrument Panel Injection Mold is created in facilities that adhere to strict environmental regulations, ensuring that the manufacturing process is both eco-friendly and sustainable. This focus on sustainability aligns with AutoTech Solutions’ broader goals of reducing environmental impact and supporting green manufacturing practices in the automotive industry.

The Automobile Instrument Panel Injection Mold offers several benefits to consumers, enhancing their overall experience with automotive interiors. The high-quality instrument panels produced using this mold technology deliver durability, aesthetics, and functionality. Consumers can enjoy the benefits of well-crafted, long-lasting instrument panels that enhance the comfort and appeal of their vehicles. Additionally, the design flexibility of the Automobile Instrument Panel Injection Mold allows for a wide range of customization options, enabling consumers to choose instrument panels that reflect their personal style and preferences.

English

English 中文简体

中文简体