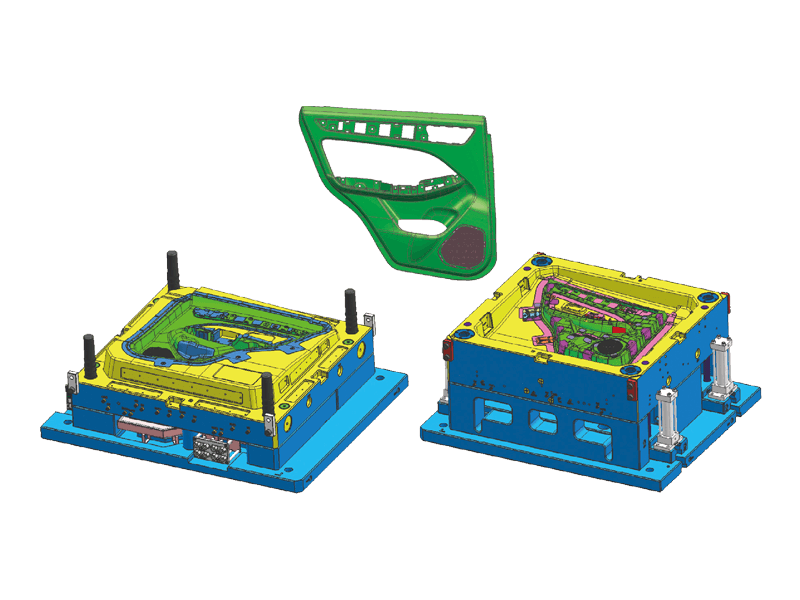

This cutting-edge advancement represents a significant breakthrough in the production of front door panels for vehicles, combining engineering with innovative design to meet the demands of modern automotive manufacturing. The introduction of the Baic Car Front Door Panel Plastic Molding is set to redefine industry standards and establish Baic as a in the global automotive market.

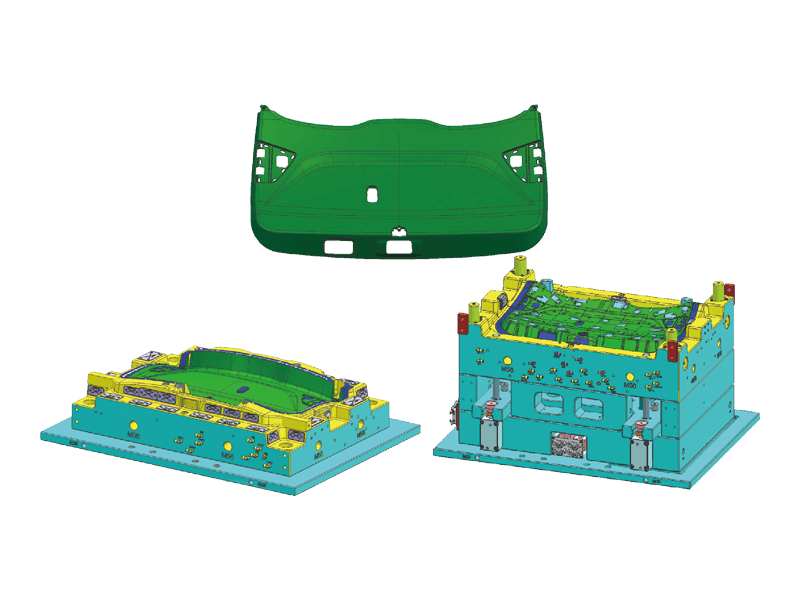

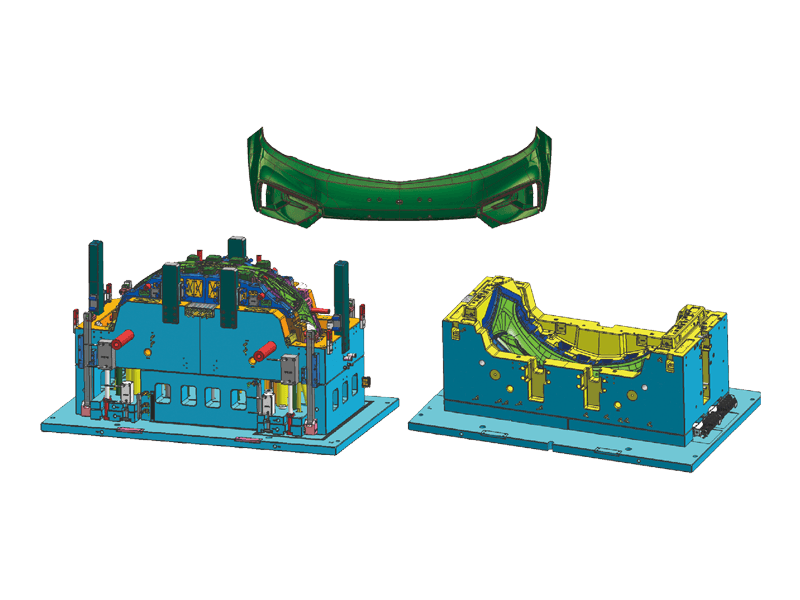

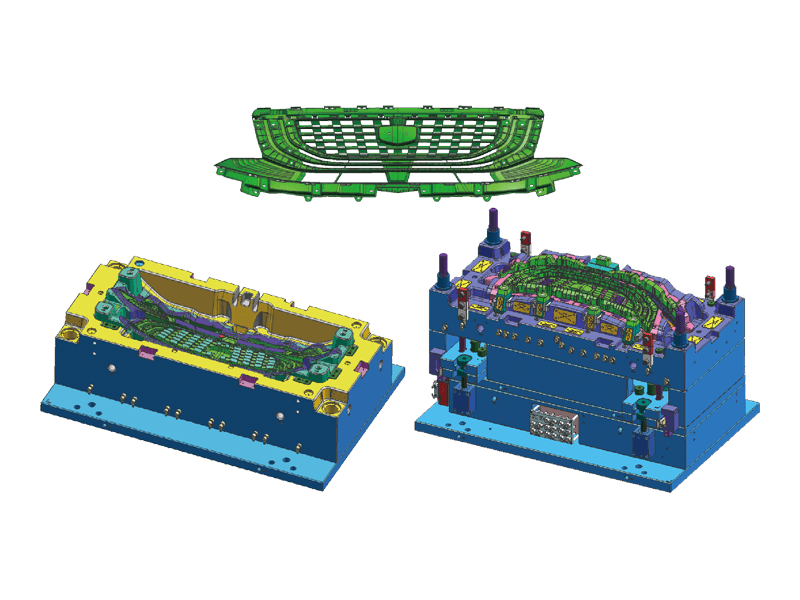

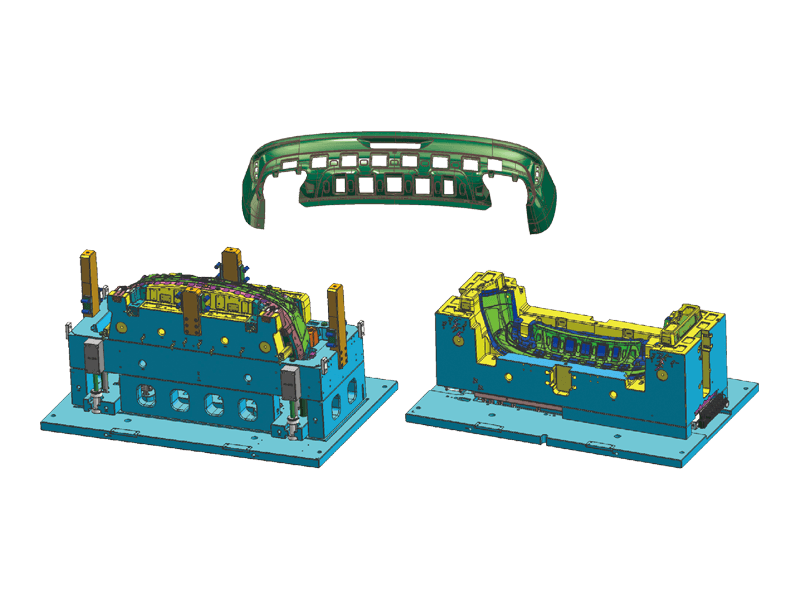

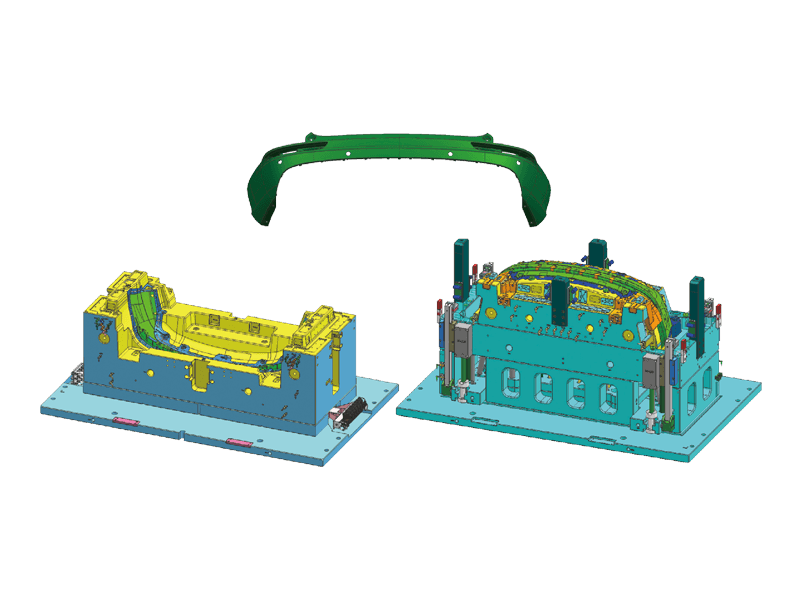

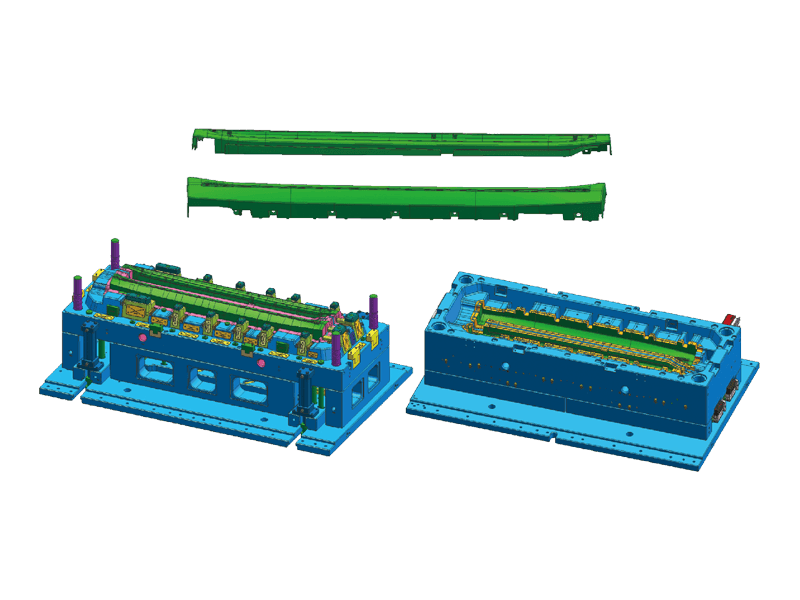

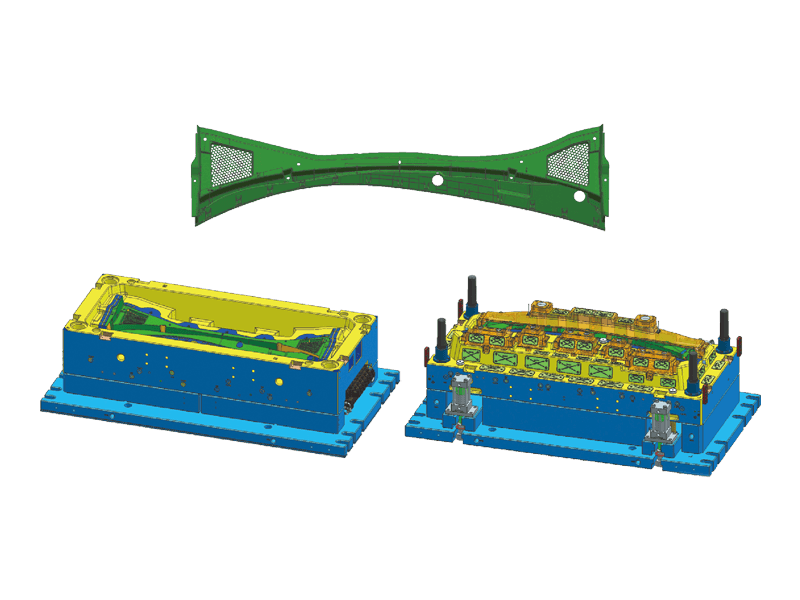

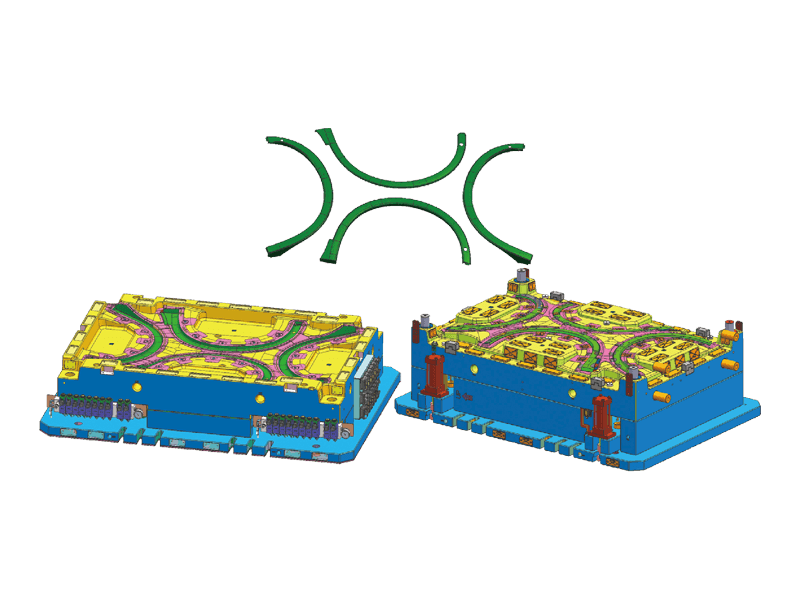

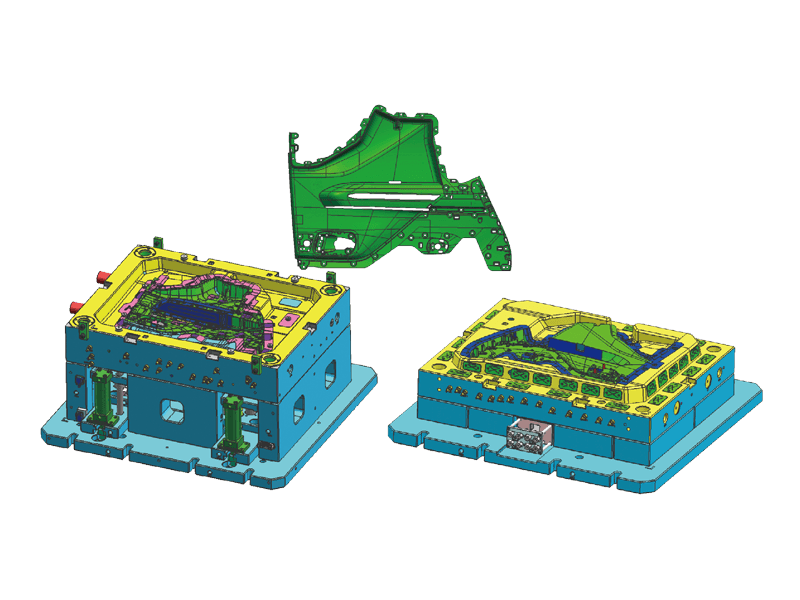

The Baic Car Front Door Panel Plastic Molding technology is designed to revolutionize the manufacturing process for front door panels. Engineered with the latest advancements in plastic molding technology, the Baic Car Front Door Panel Plastic Molding offers a new level of performance and efficiency in the creation of high-quality automotive components. This new technology not only enhances the structural integrity of front door panels but also opens up new possibilities for design and production.

One of the notable features of the Baic Car Front Door Panel Plastic Molding is its exceptional durability. Constructed from advanced plastic materials, the Baic Car Front Door Panel Plastic Molding ensures that the front door panels produced are highly resistant to environmental stressors. These include temperatures, moisture, and physical impacts, which can affect the performance and longevity of automotive components. The strength and resilience of the Baic Car Front Door Panel Plastic Molding technology make it an ideal choice for producing reliable and long-lasting front door panels for a wide range of vehicles.

The Baic Car Front Door Panel Plastic Molding offers design flexibility for automotive manufacturers. This advanced molding technology supports a variety of design options, enabling the creation of front door panels with customizable shapes, intricate textures, and diverse finishes. With the Baic Car Front Door Panel Plastic Molding, designers can explore innovative concepts and produce front door panels that not only meet functional requirements but also enhance the aesthetic appeal of modern vehicles. The design versatility offered by the Baic Car Front Door Panel Plastic Molding helps manufacturers stay ahead of design trends and offer unique products to their customers.

Efficiency is a key advantage of the Baic Car Front Door Panel Plastic Molding technology. The mold is designed to optimize the production process, enabling manufacturers to produce high-quality front door panels in a cost-effective and timely manner. The Baic Car Front Door Panel Plastic Molding features advanced design elements that streamline the manufacturing workflow, resulting in faster production cycles and reduced costs. By improving production efficiency, the Baic Car Front Door Panel Plastic Molding benefits manufacturers by lowering expenses and providing a competitive edge in the automotive market.

In keeping with Baic’s commitment to environmental sustainability, the Baic Car Front Door Panel Plastic Molding incorporates eco-friendly manufacturing practices. The technology utilizes recyclable materials and energy-efficient production methods to minimize environmental impact. The Baic Car Front Door Panel Plastic Molding reflects Baic’s dedication to green manufacturing initiatives and aligns with the company’s broader goals of reducing the ecological footprint of their products. This focus on sustainability is an integral part of the Baic Car Front Door Panel Plastic Molding development, demonstrating Baic’s commitment to environmental responsibility.

The introduction of the Baic Car Front Door Panel Plastic Molding brings numerous benefits to consumers. The advanced features of this new technology result in front door panels that offer durability, innovative designs, and enhanced performance. Consumers will appreciate the high quality and reliability of the front door panels produced with the Baic Car Front Door Panel Plastic Molding, as well as the cost-effectiveness of the manufacturing process. Additionally, the ability to customize designs ensures that consumers can choose front door panels that reflect their personal style and preferences.

English

English 中文简体

中文简体