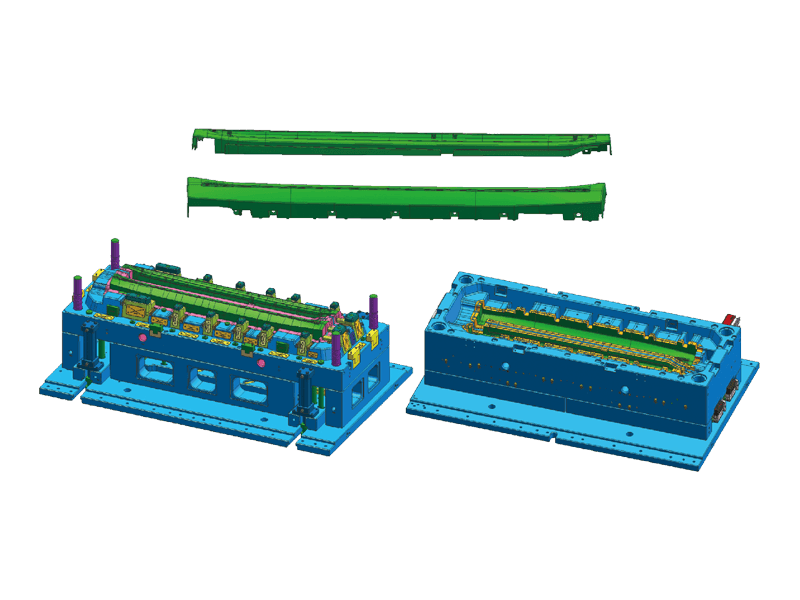

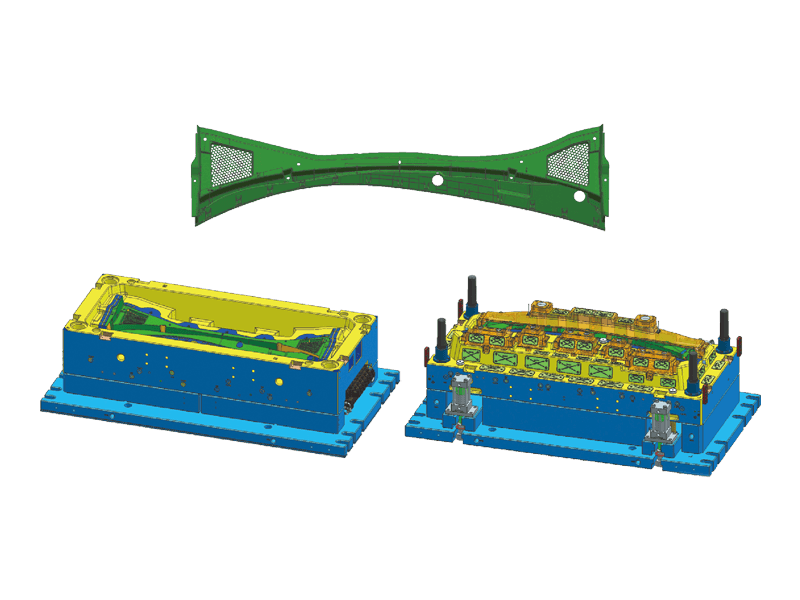

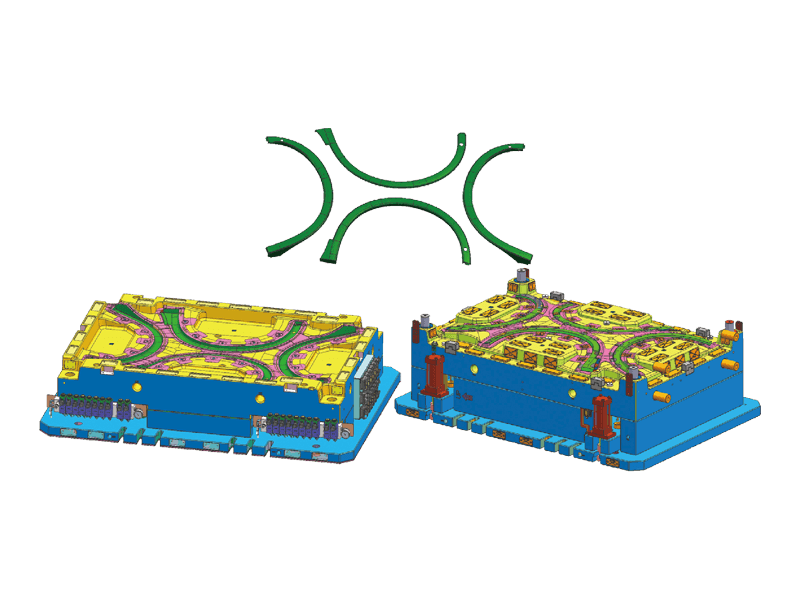

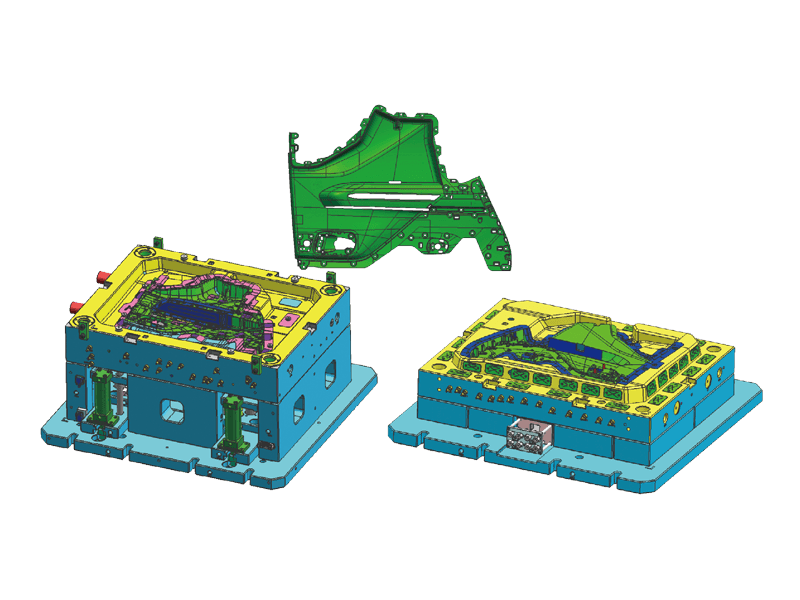

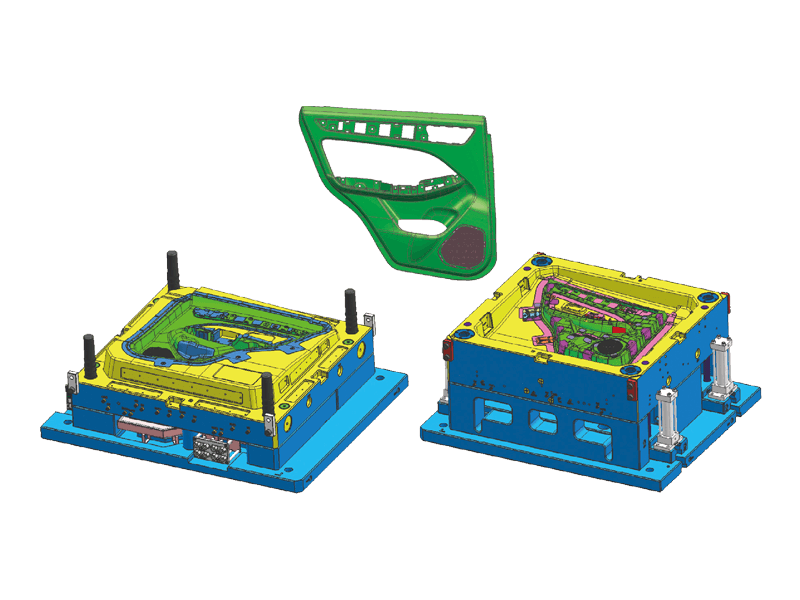

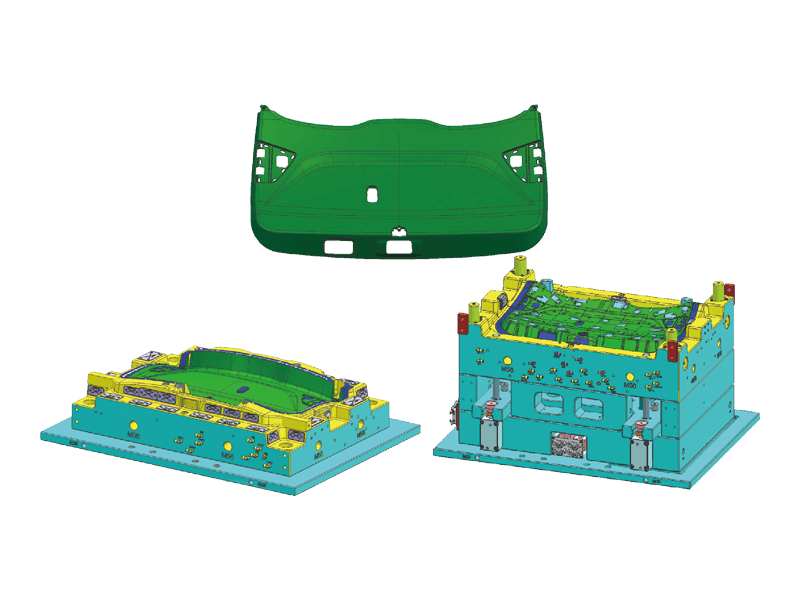

This manufacturing solution is set to transform the production of backdoor panels for automobiles, offering a range of advanced features that promise to enhance both performance and design. The introduction of the Geely Backdoor Panel Plastic Injection Molding represents a significant milestone in automotive component manufacturing and showcases Geely’s commitment to innovation and excellence.

The Geely Backdoor Panel Plastic Injection Molding technology marks a new era in the creation of high-quality backdoor panels for a variety of vehicles. Designed with the latest advancements in molding technology, the Geely Backdoor Panel Plastic Injection Molding offers a solution for producing durable, high-performance backdoor panels. This innovative approach is poised to set new standards in the automotive industry, combining cutting-edge design with efficient manufacturing processes.

One of the standout features of the Geely Backdoor Panel Plastic Injection Molding is its exceptional durability. Crafted from advanced plastic materials, the Geely Backdoor Panel Plastic Injection Molding produces backdoor panels that are designed to withstand harsh environmental conditions, including temperatures, moisture, and physical impacts. The durability of the Geely Backdoor Panel Plastic Injection Molding ensures that each backdoor panel maintains its structural integrity and performance over the long term, making it an ideal choice for both standard and heavy-duty automotive applications.

The Geely Backdoor Panel Plastic Injection Molding technology introduces a new level of design flexibility for automotive manufacturers. This advanced molding process supports a wide range of design options, allowing for the creation of backdoor panels with intricate patterns, customizable textures, and unique finishes. With the Geely Backdoor Panel Plastic Injection Molding, manufacturers can explore innovative design concepts and produce backdoor panels that not only meet but exceed contemporary automotive design standards. This flexibility ensures that the Geely Backdoor Panel Plastic Injection Molding can cater to the evolving aesthetic and functional needs of the automotive market.

Efficiency is a key advantage of the Geely Backdoor Panel Plastic Injection Molding technology. Designed for streamlined production, the Geely Backdoor Panel Plastic Injection Molding facilitates rapid and cost-effective manufacturing of backdoor panels. The mold technology features a sophisticated design that optimizes the production workflow, resulting in faster production cycles and reduced manufacturing costs. By enhancing production efficiency, the Geely Backdoor Panel Plastic Injection Molding benefits manufacturers by lowering expenses and reducing times, which ultimately translates to better value for consumers.

In line with Geely’s commitment to environmental responsibility, the Geely Backdoor Panel Plastic Injection Molding incorporates sustainable manufacturing practices. The production process for the Geely Backdoor Panel Plastic Injection Molding utilizes recyclable materials and energy-efficient techniques to minimize environmental impact. This focus on sustainability reflects Geely’s dedication to reducing the ecological footprint of their products and supporting green manufacturing initiatives. By prioritizing eco-friendly practices, the Geely Backdoor Panel Plastic Injection Molding aligns with Geely’s broader goals of promoting environmental sustainability in the automotive industry.

The introduction of the Geely Backdoor Panel Plastic Injection Molding technology offers a range of benefits for consumers. The advanced features of the mold technology result in high-quality backdoor panels that provide both functional and aesthetic advantages. Consumers can look forward to backdoor panels that offer durability, innovative designs, and enhanced performance. Additionally, the cost-effective production processes enabled by the Geely Backdoor Panel Plastic Injection Molding ensure that these high-quality components are available at competitive prices, making them an attractive option for both automotive manufacturers and vehicle owners.

English

English 中文简体

中文简体