The automotive industry is experiencing a significant transformation, driven by advancements in manufacturing technologies. Among these, the development and widespread adoption of Automobile Car Injection Mold technology stand out as a key factor in enhancing production efficiency, reducing costs, and improving the quality of vehicles. As the demand for high-performance, durable, and aesthetically appealing cars continues to grow, the role of Automobile Car Injection Mold in the manufacturing process becomes increasingly critical.

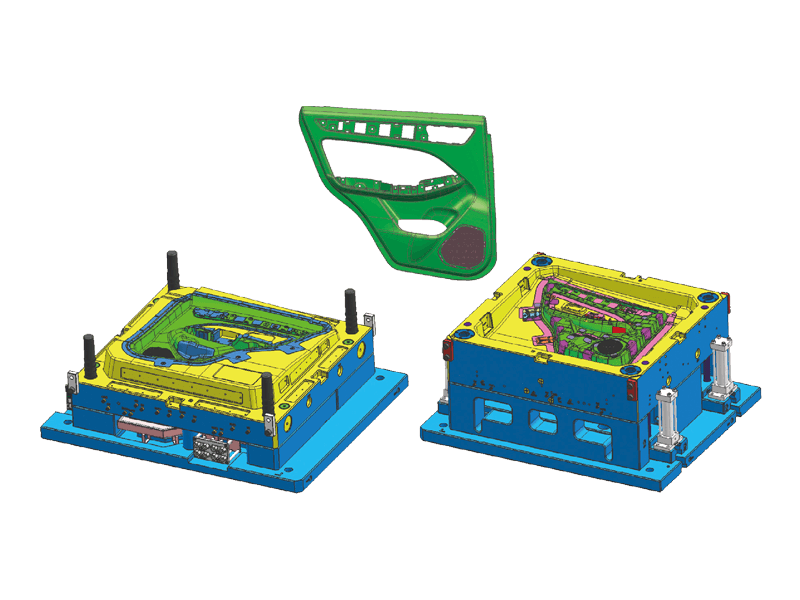

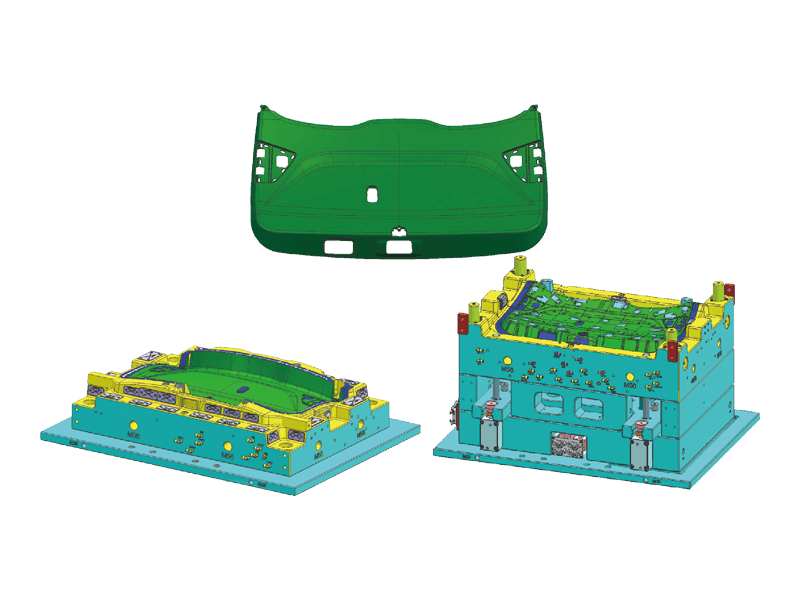

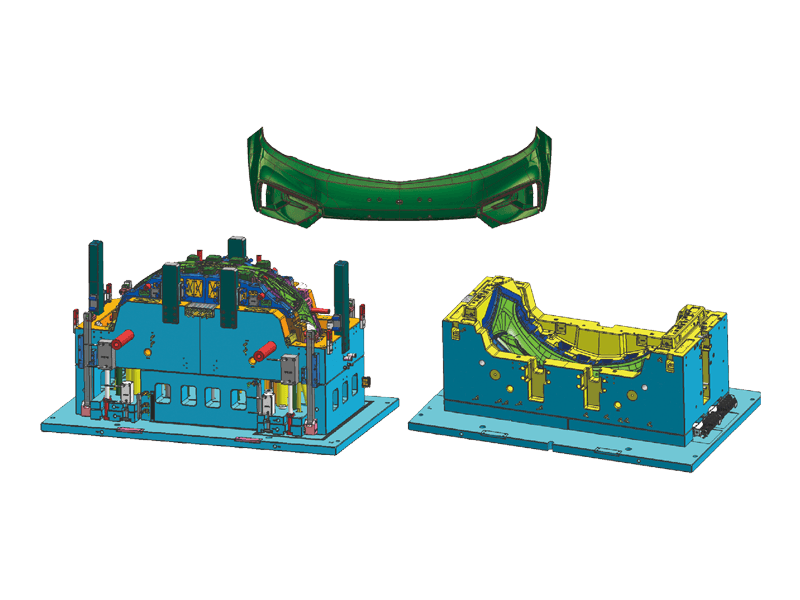

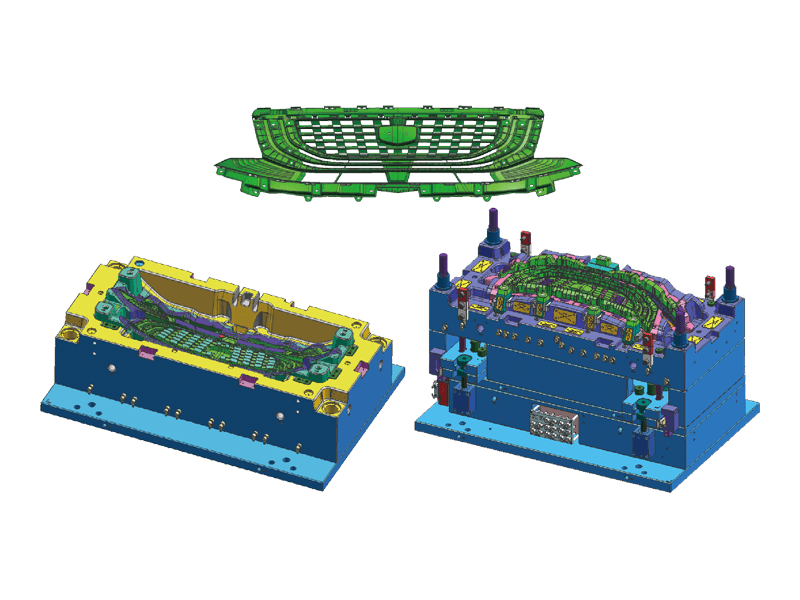

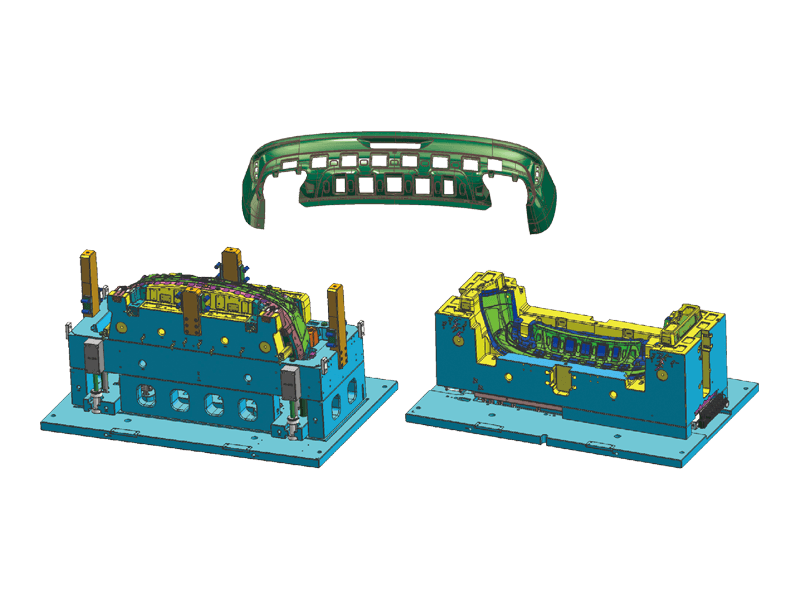

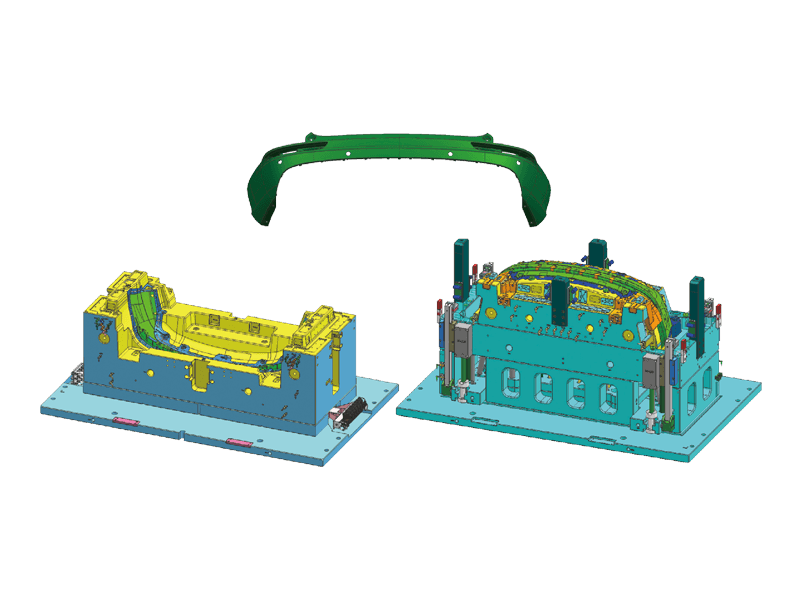

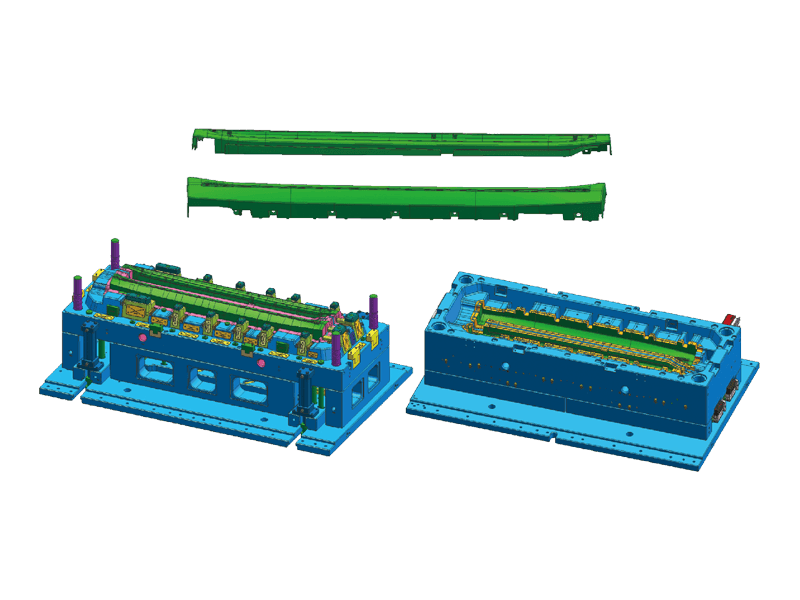

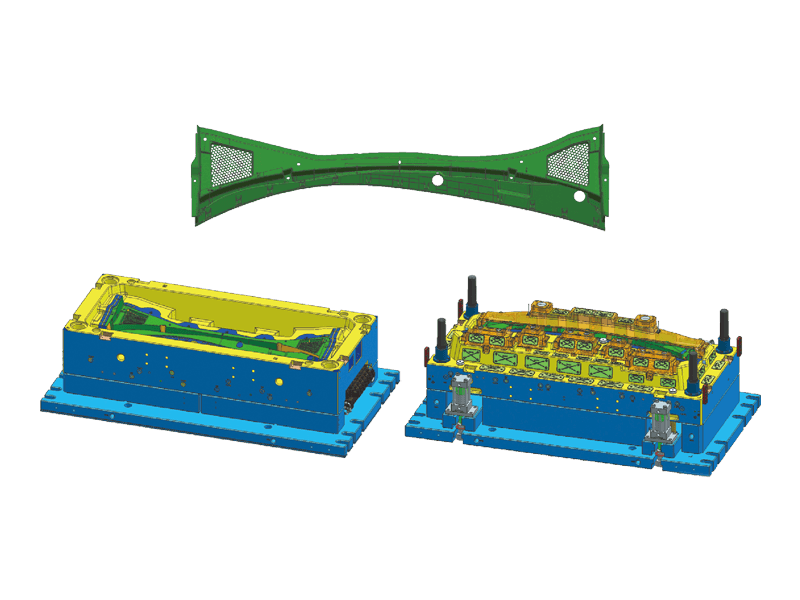

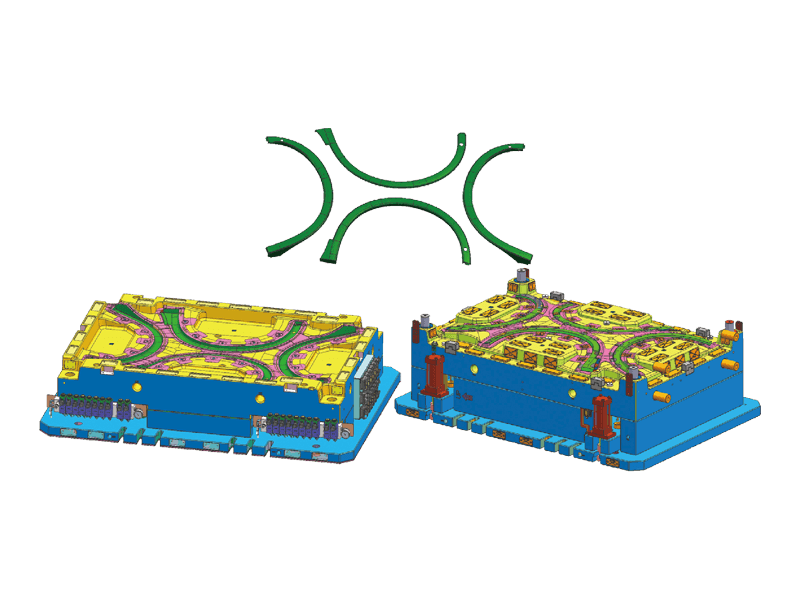

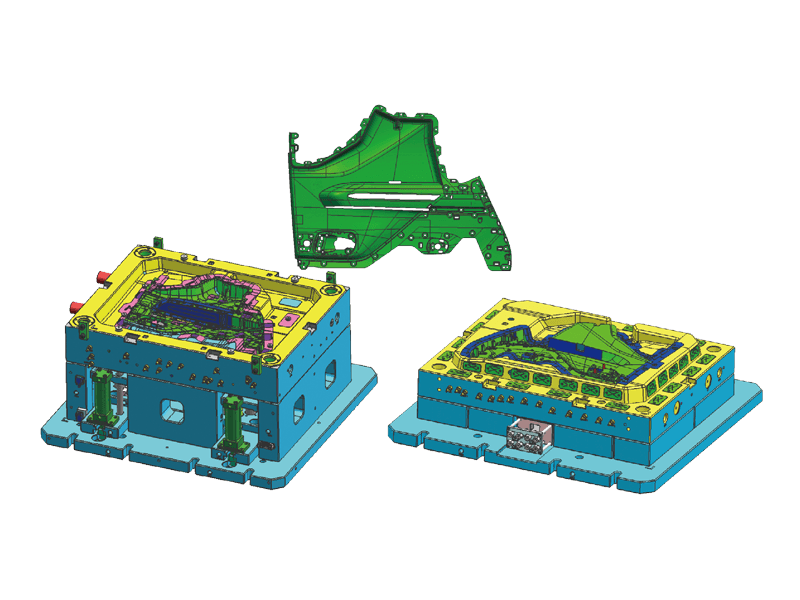

Automobile Car Injection Mold technology involves the precise molding of plastic components used in vehicle manufacturing. These components range from dashboard panels and bumpers to intricate interior parts and under-the-hood elements. The versatility of Automobile Car Injection Mold allows manufacturers to produce a wide variety of parts with exact specifications, ensuring that each component meets the stringent quality standards required in the automotive industry.

One of the primary advantages of Automobile Car Injection Mold technology is its ability to produce parts with exceptional accuracy and consistency. This precision is essential in the automotive industry, where even the smallest deviation from design specifications can to performance issues or safety concerns. The use of high-quality molds ensures that each part produced is identical, which is crucial for maintaining the integrity and functionality of the final product. This consistency also plays a significant role in reducing waste, as fewer defective parts are produced, to cost savings and a more sustainable manufacturing process.

Another notable benefit of Automobile Car Injection Mold technology is its efficiency. The injection molding process is highly automated, allowing for the rapid production of large volumes of parts. This speed is particularly beneficial in the automotive industry, where meeting production deadlines is critical. The ability to quickly and efficiently produce parts using Automobile Car Injection Mold technology enables manufacturers to respond to market demands more effectively, whether they are ramping up production of a popular model or introducing a new vehicle to the market.

Durability is another key feature of parts produced through Automobile Car Injection Mold technology. The materials used in injection molding, typically high-grade plastics, are chosen for their strength and resilience. These materials can withstand the rigors of everyday use, from exposure to temperatures to the stresses of road conditions. As a result, parts produced using Automobile Car Injection Mold technology are not only durable but also contribute to the overall safety and longevity of the vehicle.

In addition to its technical advantages, Automobile Car Injection Mold technology also offers significant design flexibility. The ability to create complex shapes and detailed features is a major benefit, allowing designers to push the boundaries of automotive aesthetics and functionality. Whether it's creating sleek, aerodynamic body panels or intricate interior details, Automobile Car Injection Mold technology provides the tools needed to bring innovative designs to life. This flexibility is crucial in an industry where consumer preferences are constantly evolving, and manufacturers must stay ahead of trends to remain competitive.

The environmental impact of manufacturing is an increasingly important consideration in today's automotive industry. Automobile Car Injection Mold technology supports sustainable practices by minimizing material waste and enabling the use of recyclable plastics. The precision of the molding process ensures that excess material is kept to a minimum, reducing the overall environmental footprint of production. Additionally, the ability to use recycled plastics in the injection molding process further enhances the sustainability of the automotive manufacturing process.

Manufacturers who have integrated Automobile Car Injection Mold technology into their production lines are already seeing the benefits. Many report significant improvements in both the speed and quality of their manufacturing processes, to increased customer satisfaction and stronger sales performance. The ability to produce high-quality parts quickly and efficiently gives these manufacturers a competitive edge in a crowded market, where consumers are looking for vehicles that offer both performance and value.

English

English 中文简体

中文简体