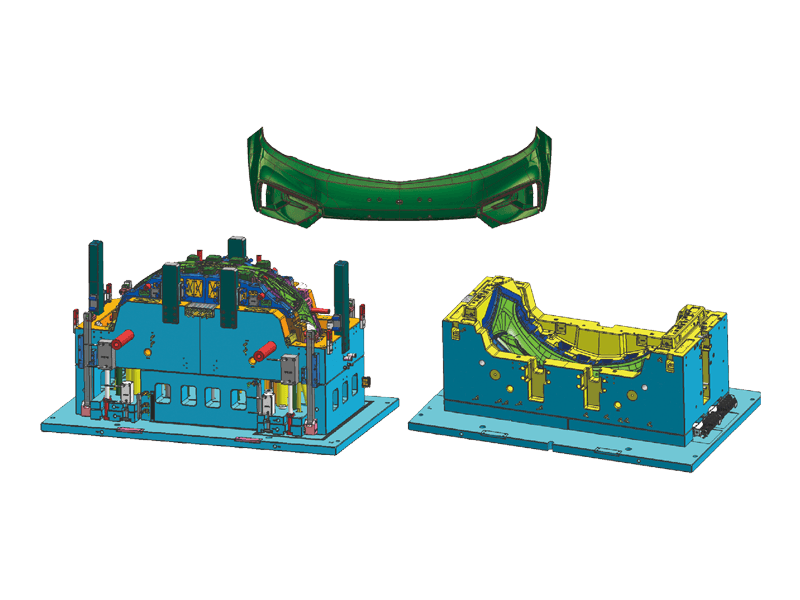

The automotive industry is constantly evolving, with manufacturers seeking innovative ways to enhance vehicle aesthetics, functionality, and safety. One such innovation that is gaining traction is the Two-color Low Pressure Injection Bumper Mold. This technology is set to revolutionize the way bumpers are designed and manufactured, offering a new level of customization and efficiency. In this article, we will delve into the details of this groundbreaking technology and its potential impact on the industry.

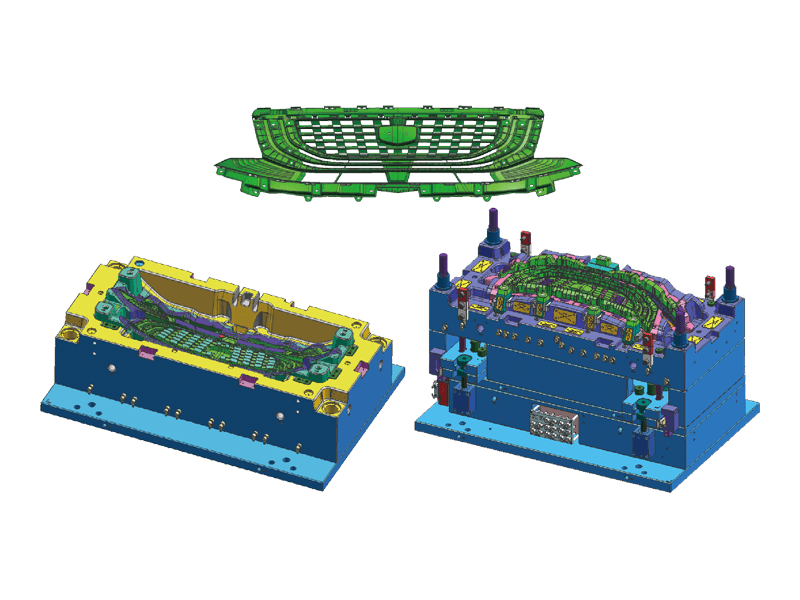

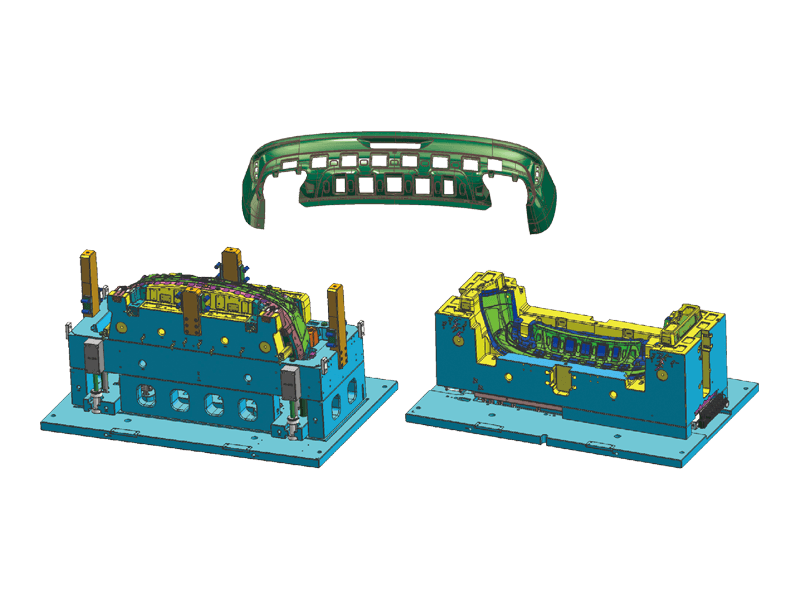

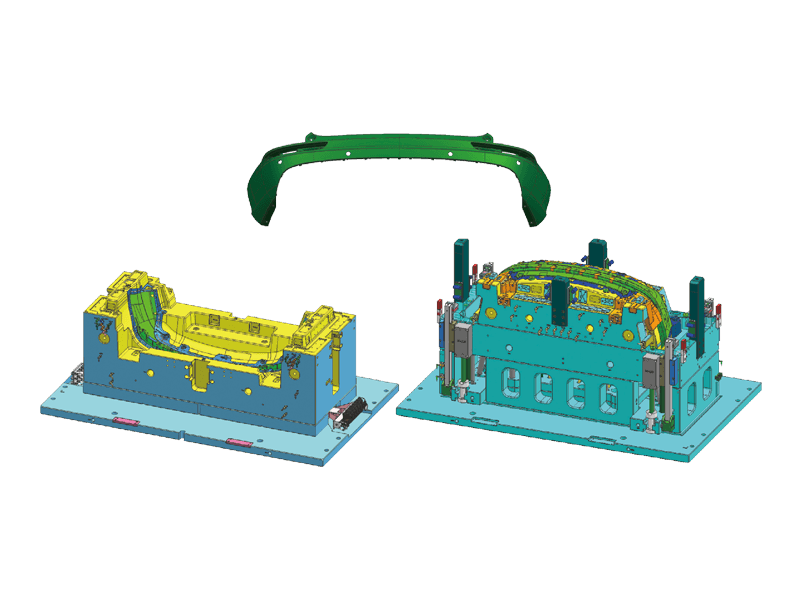

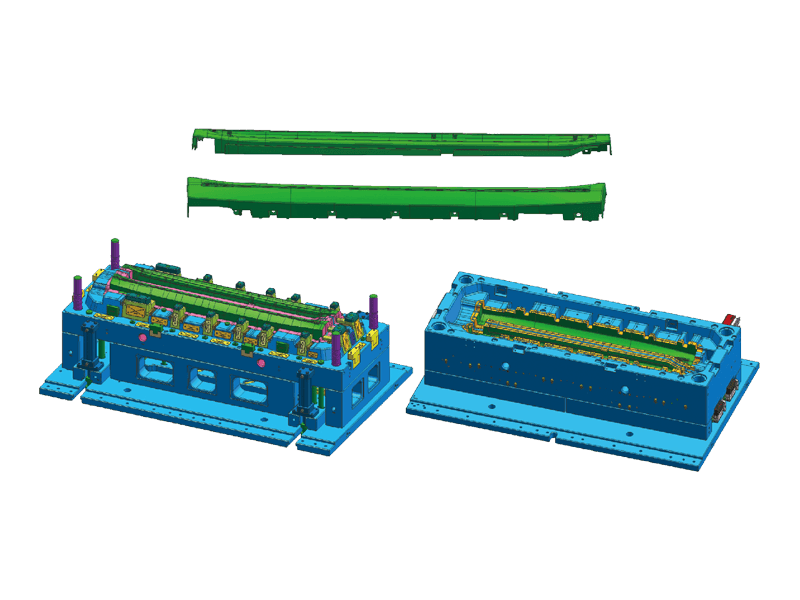

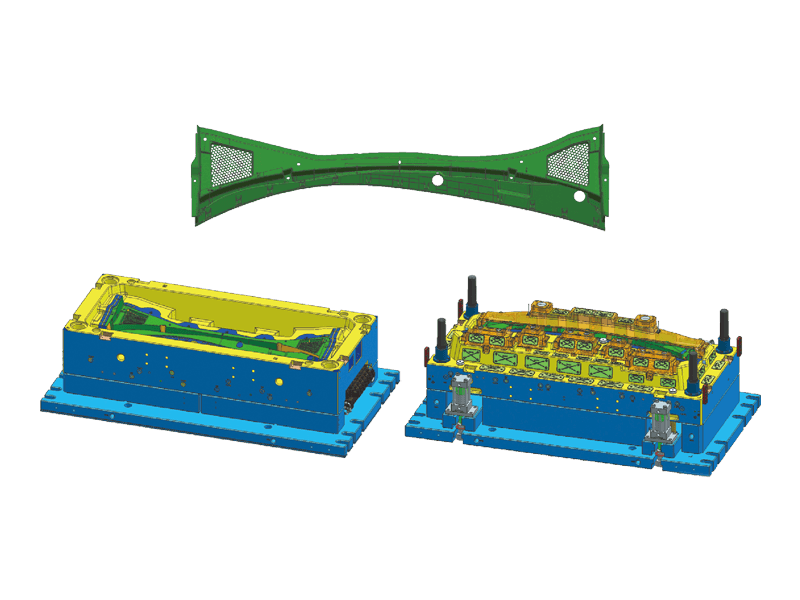

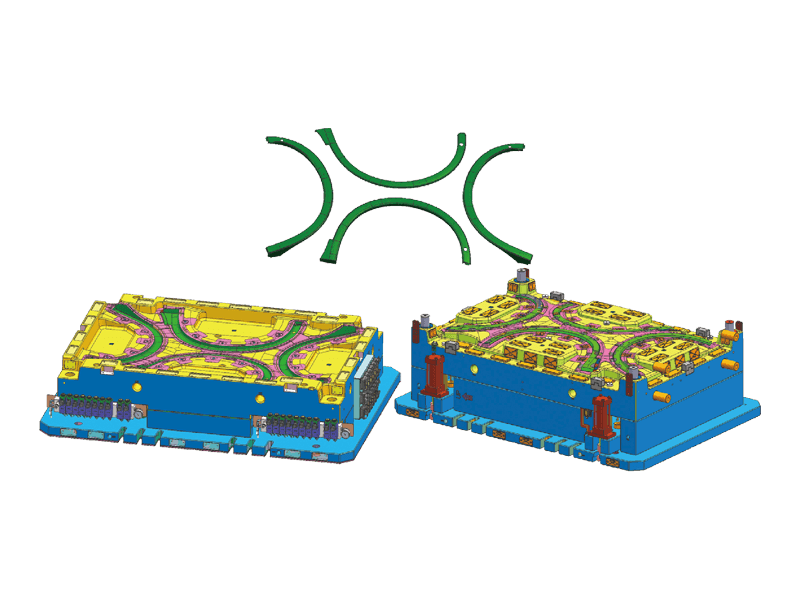

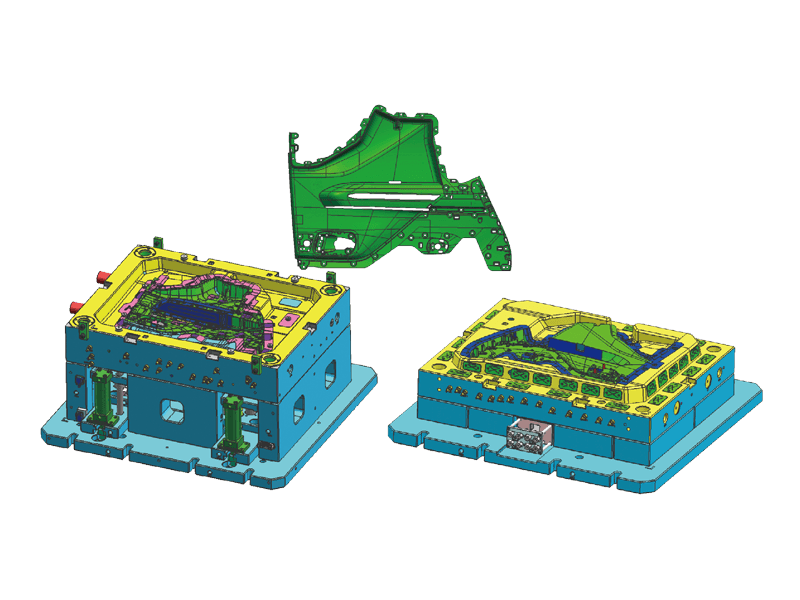

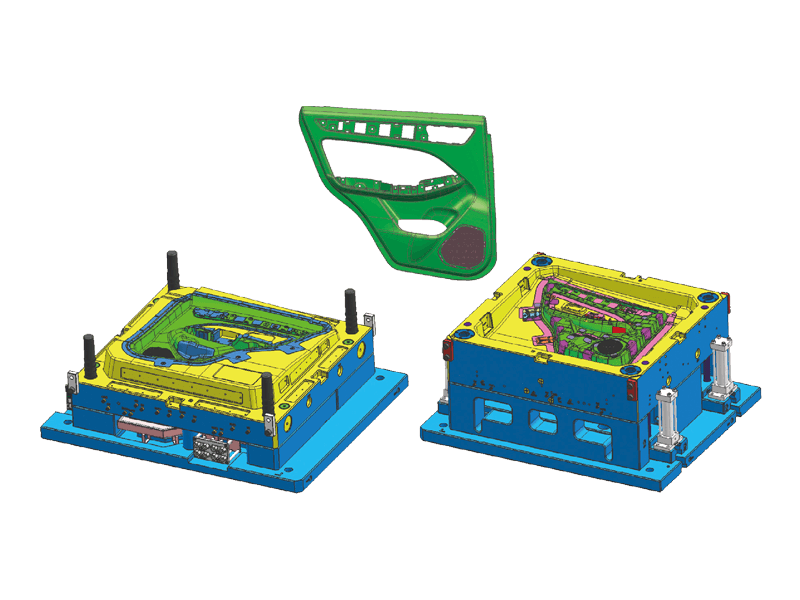

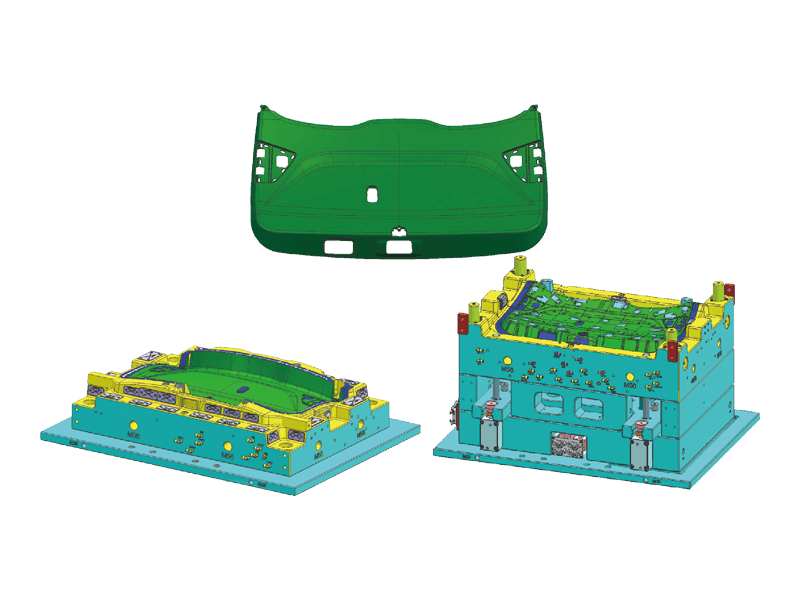

A Two-color Low Pressure Injection Bumper Mold is a specialized tool used in the automotive industry to create bumpers with two distinct colors and a lower injection pressure. This innovative mold allows for the simultaneous injection of two different materials, resulting in a bumper that is not only visually appealing but also structurally robust.

The use of Two-color Low Pressure Injection Bumper Molds offers several advantages over traditional single-color molds:

a. Aesthetic Appeal: The ability to create bumpers with two distinct colors adds a new level of customization to vehicle design, allowing manufacturers to create unique and eye-catching vehicles.

b. Structural Integrity: The lower injection pressure used in the process results in a more uniform distribution of material, to a stronger and more durable bumper.

c. Cost Efficiency: By using two materials simultaneously, manufacturers can reduce the number of production steps, to cost savings and increased efficiency.

Several automotive manufacturers have already begun to adopt Two-color Low Pressure Injection Bumper Molds in their production processes. This adoption has led to a surge in innovation, with manufacturers exploring new design possibilities and material combinations.

a. Material Innovations: The use of different materials in the Two-color Low Pressure Injection Bumper Mold process has led to the development of bumpers with improved impact resistance and durability.

b. Design Flexibility: Manufacturers are now able to experiment with a wider range of colors and textures, to more diverse and visually appealing vehicle designs.

Despite the numerous benefits, the implementation of Two-color Low Pressure Injection Bumper Molds also presents some challenges:

a. Technical Complexity: The process of injecting two materials simultaneously requires precise control and coordination, which can be technically challenging.

b. Cost of Implementation: The initial investment in new molds and equipment can be significant, potentially deterring some manufacturers from adopting the technology.

Solutions to these challenges include ongoing research and development to refine the process, as well as partnerships between manufacturers and mold suppliers to share the costs and risks associated with implementation.

The future looks bright for the Two-color Low Pressure Injection Bumper Mold technology. As more manufacturers recognize the benefits of this innovative process, it is expected to become a standard in the automotive industry. The potential for further advancements in material science and design capabilities is vast, promising even more exciting developments in the years to come.

The introduction of the Two-color Low Pressure Injection Bumper Mold marks a significant milestone in the automotive industry. This technology not only enhances the visual appeal of vehicles but also improves their structural integrity and production efficiency. As the industry continues to embrace this innovation, we can expect to see a new wave of creative and durable bumper designs hitting the roads.

In the ever-competitive world of automotive manufacturing, the adoption of Two-color Low Pressure Injection Bumper Molds is a testament to the industry's commitment to innovation and excellence. As this technology continues to evolve, it will undoubtedly play a pivotal role in shaping the future of automotive design and production.

English

English 中文简体

中文简体