In the fast-paced world of automotive engineering, innovation is key to staying ahead of the competition. One of the latest advancements in vehicle design that exemplifies this innovation is the Geely Radiator Grille Injection Molding. This cutting-edge technology not only enhances the aesthetic appeal of vehicles but also contributes significantly to their performance and durability. In this article, we will explore the various aspects of the Geely Radiator Grille Injection Molding, from its technical benefits to its impact on the automotive industry.

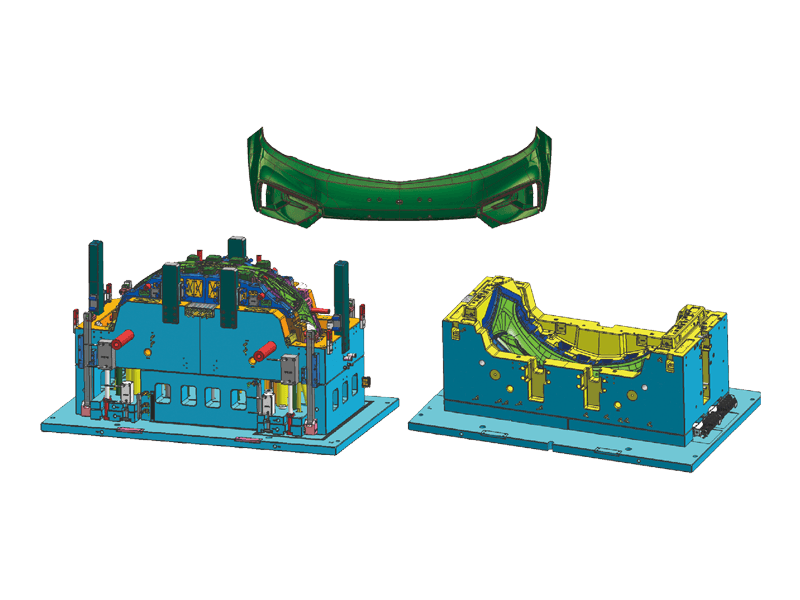

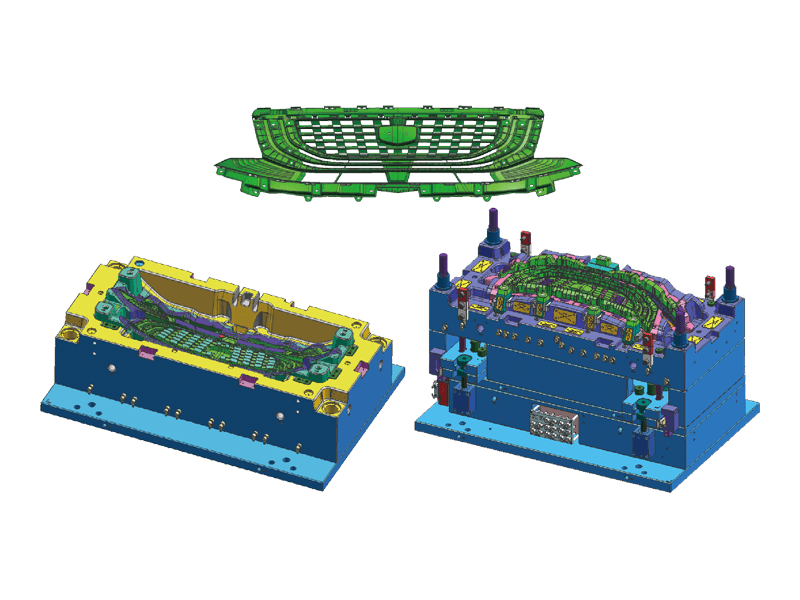

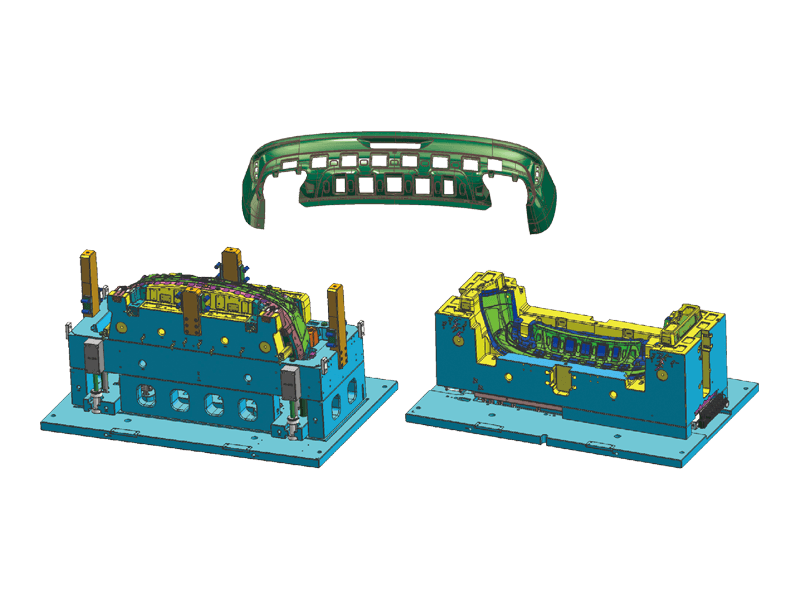

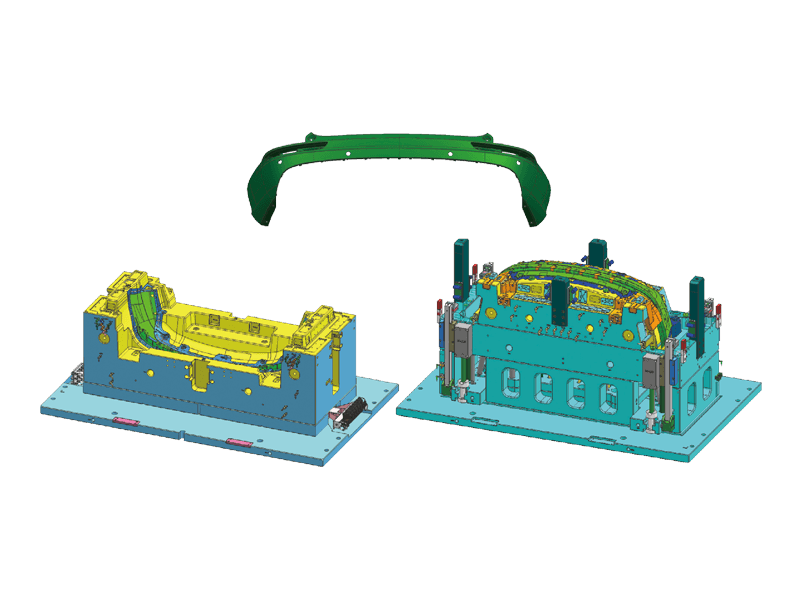

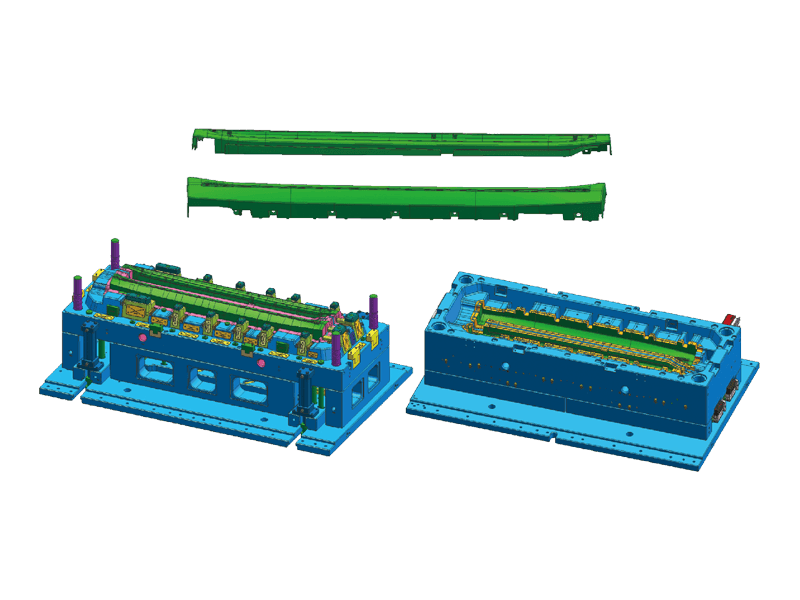

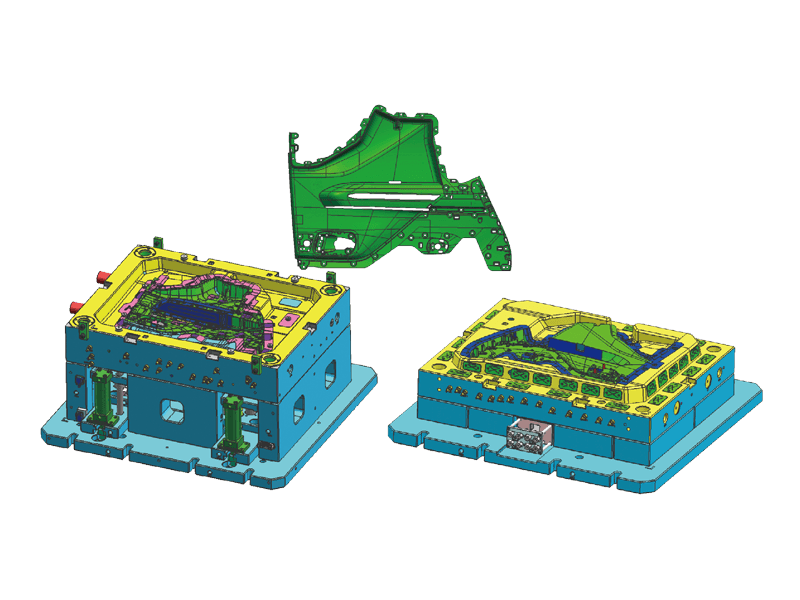

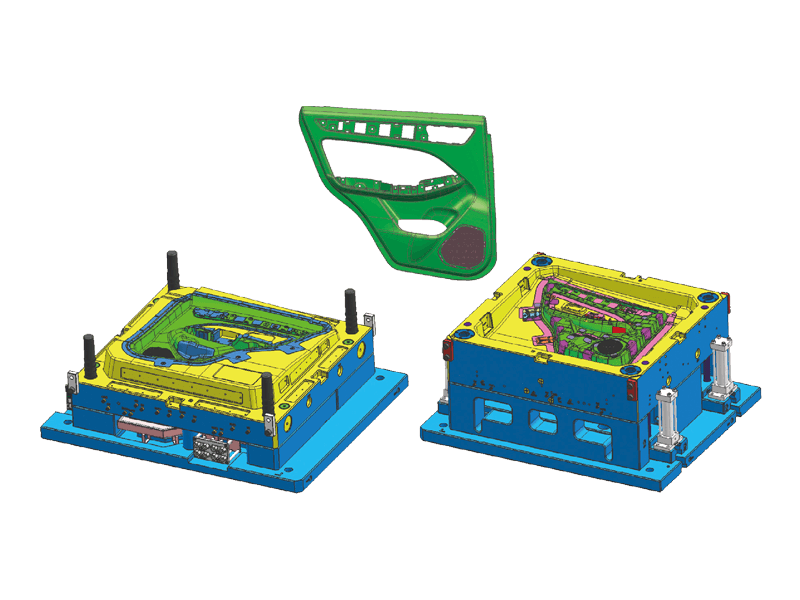

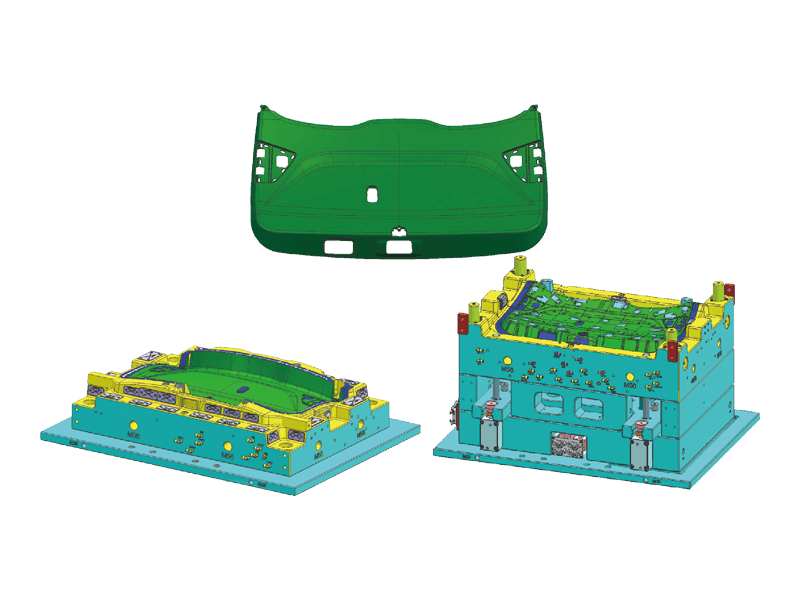

The Geely Radiator Grille Injection Molding represents a significant leap forward in the production of vehicle grilles. Injection molding is a manufacturing process where molten material is injected into a mold to produce a wide range of parts and components. In the case of Geely, this process is used to create the intricate and stylish designs of the radiator grille, which serves both functional and aesthetic purposes in their vehicles.

One of the primary advantages of Geely Radiator Grille Injection Molding is the precision and consistency it offers. Traditional manufacturing methods can often to variations in product quality, but the injection molding process ensures that each grille produced meets exact specifications. This precision is crucial for maintaining the high standards of Geely’s vehicles, as every Geely Radiator Grille Injection Molding part must fit perfectly and perform reliably in various conditions.

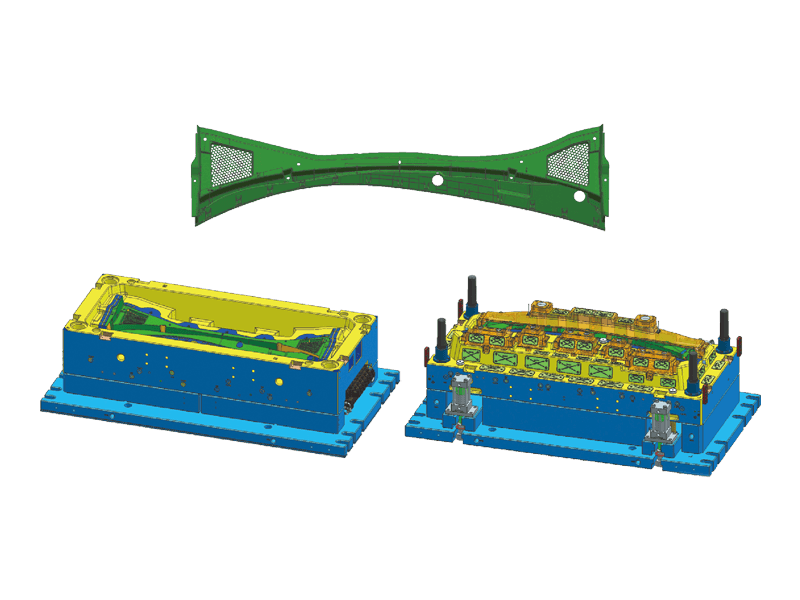

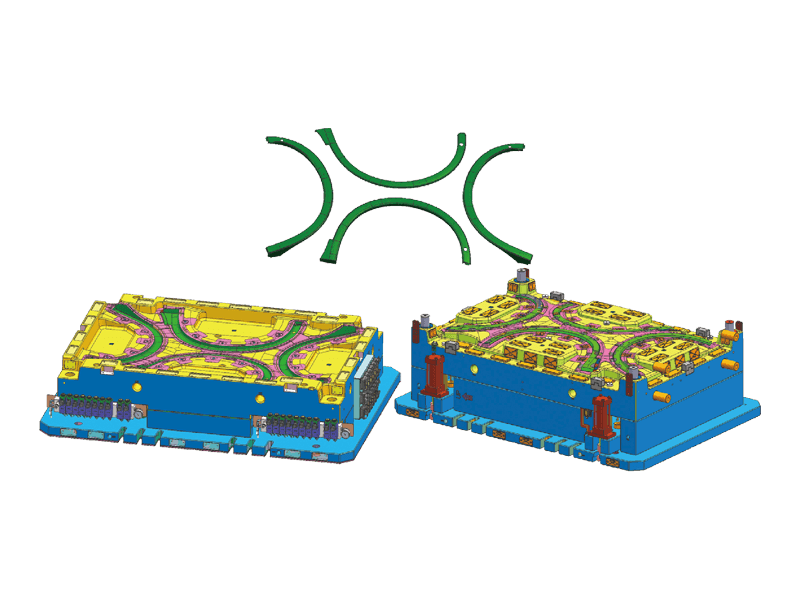

The design capabilities of Geely Radiator Grille Injection Molding are also noteworthy. Injection molding allows for the creation of complex and detailed grille designs that might be difficult or impossible to achieve with other manufacturing techniques. Geely leverages this capability to produce grilles with intricate patterns, unique textures, and sophisticated finishes. These design elements not only enhance the visual appeal of their vehicles but also contribute to their aerodynamic efficiency. By optimizing the airflow through the radiator grille, Geely is able to improve the vehicle’s performance and fuel efficiency.

Another significant benefit of Geely Radiator Grille Injection Molding is the durability of the grilles produced. The materials used in the injection molding process are selected for their strength and resilience, which ensures that the grilles can withstand the rigors of everyday driving. Whether it’s exposure to harsh weather conditions or the impact of road debris, the Geely Radiator Grille Injection Molding process produces grilles that are built to last. This durability is a key factor in maintaining the vehicle’s appearance and functionality over time.

The environmental impact of the Geely Radiator Grille Injection Molding process is also a point of interest. Geely is committed to sustainable manufacturing practices, and this commitment is reflected in their use of eco-friendly materials and processes. The injection molding process itself is highly efficient, with minimal waste generated during production. Additionally, the materials used in the Geely Radiator Grille Injection Molding process are often recyclable, aligning with Geely’s broader goals of reducing their environmental footprint.

The integration of advanced technologies into the Geely Radiator Grille Injection Molding process is another area where Geely is making strides. Modern injection molding machines are equipped with sophisticated control systems that monitor and adjust the production process in real-time. These technologies help to ensure the levels of quality and consistency in every Geely Radiator Grille Injection Molding part produced. The use of these advanced technologies demonstrates Geely’s commitment to leveraging the latest innovations to improve their manufacturing processes.

In addition to its technical advantages, the Geely Radiator Grille Injection Molding process also plays a role in the customization of Geely vehicles. The ability to create a wide range of grille designs allows customers to choose from various styles and finishes to suit their personal preferences. Whether it’s a sleek, modern design or a more traditional look, the Geely Radiator Grille Injection Molding process offers options that cater to diverse tastes and requirements. This level of customization enhances the customer experience and allows Geely to offer products that are tailored to individual needs.

English

English 中文简体

中文简体